Tips and Tricks for you

What a wonderful car here

Need repair? Help yourself!

Search

Recent on Blogar

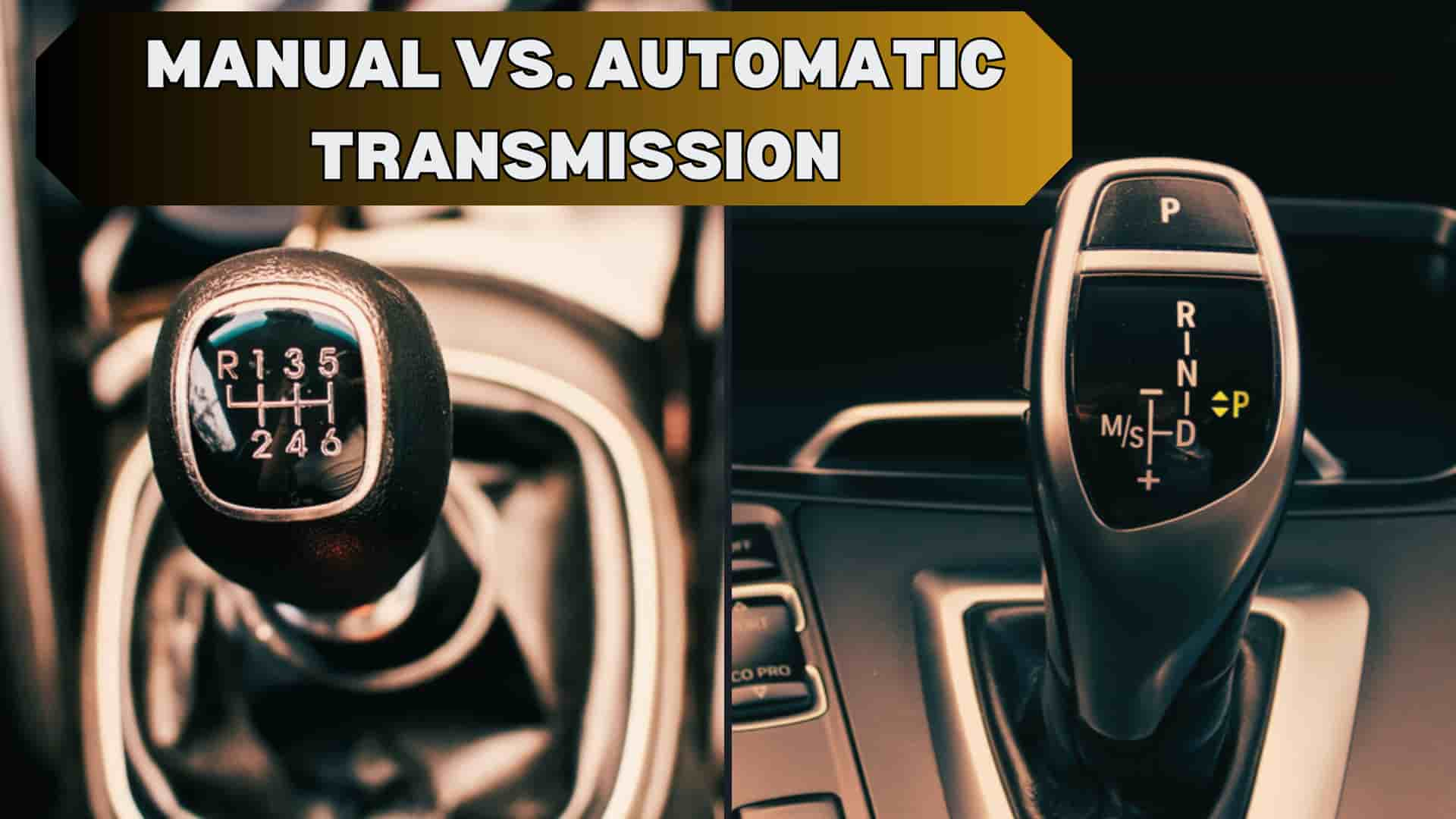

Manual vs. Automatic Transmissions: What’s the Difference?

- October 6, 2024

- 3 min read

Let's fit a new speedometer cable

- September 21, 2024

- 6 min read

A Shocking Shift: Why Are Drivers Turning

- September 3, 2024

- 2 min read