Avoiding tyre wear

Caused by over-inflation.

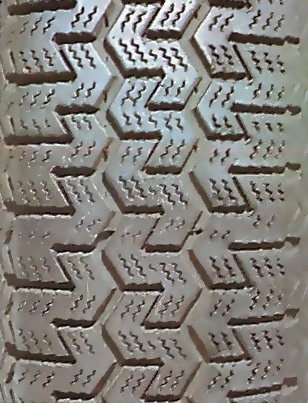

The tyre has been run at too low a pressure. Wheel misalignment such as excessive toe-in or toe-out. Constant hard cornering at high speeds. Different wear patterns are an indication of the cause of abnormal tyre wear. But the cause is not always obvious, and a tyre may have excessive wear from more than one fault. If a car is driven continually with the tyre pressures too high, most of its load is carried on the centre of the tread, which wears out faster than the shoulders. If it is driven continually with the tyre pressures too low, the tread on the shoulders wears faster than the centre tread. Feathering, lifting of the tread at the groove edges, is one of the first signs that the wheels are out of alignment. The damage is caused by the wheel being dragged sideways as it moves forwards. When wheels are misaligned, feathering is followed by excessive shoulder wear. If the wheels are pointing inwards (toeing-in), the outside shoulders are worn, predominantly on the passenger side, where it is exaggerated by the road camber. If the wheels are toeing-out, the inside shoulders are worn, this time predominantly on the driver’s side. Severe shoulder wear together with scooped-out parts in the centre of the tread indicates excessive wear in the suspension linkages, causing the wheels to flutter on the road surface as they go forwards. Caused by friction and heat from harsh motoring. Constant fierce braking or faulty brakes. Heavy braking will eventually cause a bare patch. Exposed cords due to locked-wheel braking at high speeds. Cornering at speed puts extra strain on one shoulder of a tyre, according to the direction of the turn. Constant hard cornering is likely to result in severe rasping of both shoulders of a tyre. Friction and heat from harsh motoring can lead to distortion, or ridging, of the tread. Continual fierce braking (or faulty brakes) rasps the rubber from patches of tyre tread, leading to a bare patch a brake flat – that may eventually expose the crown plies and wear a hole in the casing. Press the gauge cup over the valve. Replace the valve cap finger tight when you finish. Wrong tyre pressures – particularly pressures that are too low – lead to rapid tread wear or even total tyre failure, and can affect handling. Make regular fortnightly checks, as well as checking before the start of a long journey. Because tyre pressure increases rapidly when the tyres get hot during running, always check pressures when the tyres are cold, before the car has been driven. Use a reliable pressure gauge or foot pump, preferably your own air-line gauges at garages can be unreliable. Inflate to the pressures recommended by the car manufacturer, given in the car handbook or service manual. Make sure tyres on the same axle are inflated to the same pressure. Remember that tyres should be adjusted for load carrying, towing and high-speed driving. Follow the recommendations given in the car handbook or service manual, or refer to the tyre manufacturers. If the figures are not available, as a rough guide increase rear tyres 4-6 psi for a maximum load or when towing, and all tyres 3-6 psi for sustained high-speed driving. Do not lower tyre pressures in bad weather. It does not give a better grip on snow, ice or wet roads – in fact it closes the tread pattern and reduces grip, as well as damaging the tyre carcass.

Checking tyre pressure